Working Principle

The walnut blaster uses high-pressure airflow to blast walnut shell abrasive into the engine intake pipelines. The high-speed rolling and impact of the abrasive particles within the enclosed pipes effectively remove carbon deposits from the intake valves and cylinder walls. During the cleaning process, the specialized recovery nozzle’s suction tube collects the walnut shell abrasive mixed with carbon deposits and channels it into the sand storage tank for reuse.

AUTOOL HTS728 Walnut Blaster Features

Engine Combustion Chamber Cleaning: Blasts cleaning directly into the combustion chamber via the spark plug hole, eliminating the need for disassembly.

Intake Manifold Cleaning: Sequentially cleans each intake manifold using blasting, ensuring thorough carbon removal.

Intake/Exhaust Valve Cleaning: Cleans intake and exhaust valves sequentially with blasting, without the need for disassembly.

Multiple Adapters: Equipped with 5 adapters, supporting a variety of vehicle models.

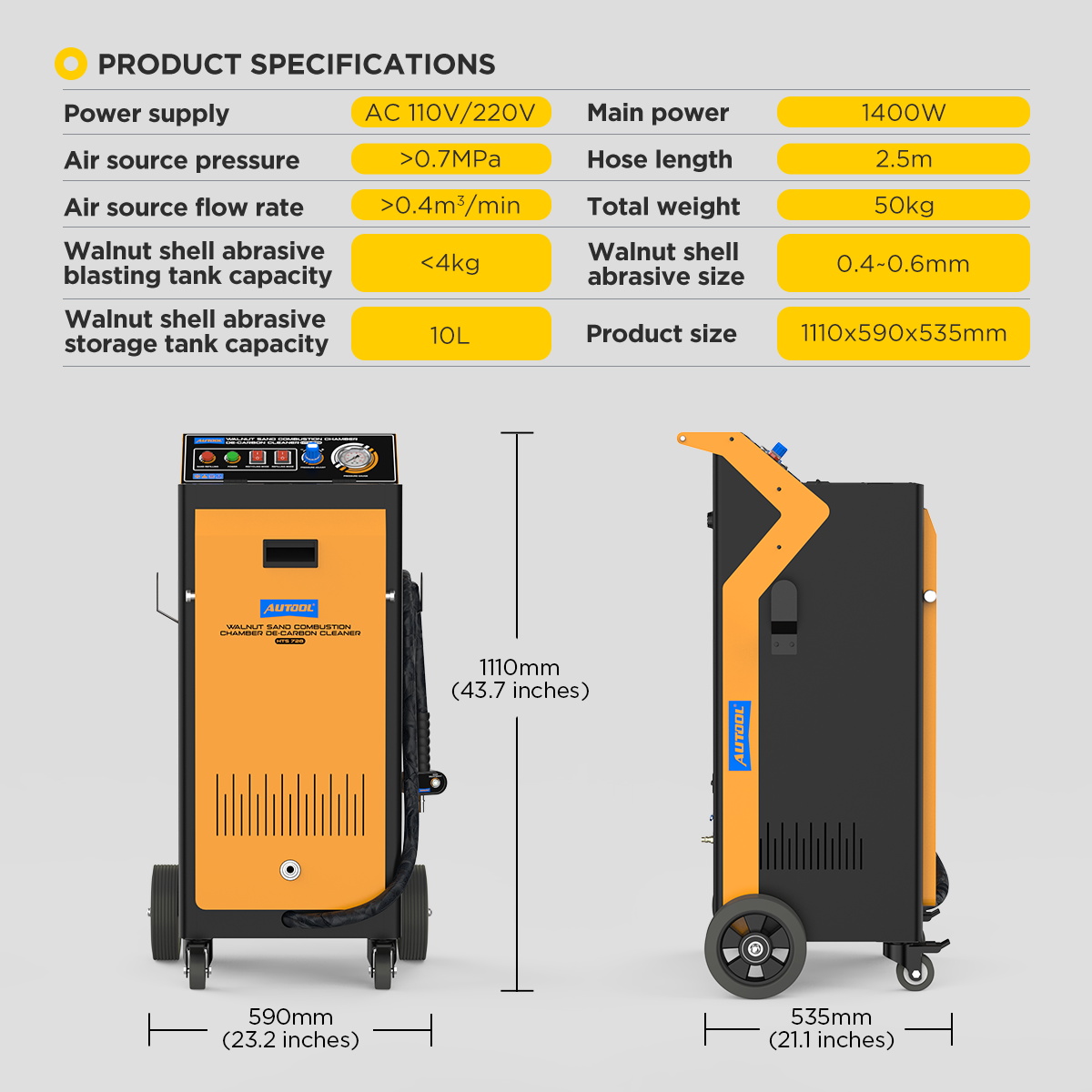

External Air Source Design: The machine is powered by a 1400W high-performance motor, which uses an external air source to provide continuous power. This enhances the impact force of the walnut shell abrasive, ensuring thorough removal of carbon deposits from the engine pipes.

Built-in HEPA Filter: The equipment performs spraying and recovery simultaneously. The filter separates the walnut shell abrasive from the carbon deposits, ensuring that the walnut shell abrasive can be reused, while preventing residual particles from damaging the exhaust system at high temperatures.

Integrated Design: The walnut shell abrasive is recycled within the equipment, and no manual recovery is required, saving time and effort.

User-Friendly: Equipped with a swivel caster that can rotate 360°, making it easy to move and operate.

3-Year Warranty: For damage caused by non-human factors, we promise to resend parts for free within 3 years. If you have any problems, please contact us, and we will respond within 24 hours!

Operating Instructions

1. After unpacking, place the AUTOOL HTS728 Walnut Blaster in the workspace. Take out the walnut sand abrasive recovery suction pipe from the accessory storage box and attach it to the walnut sand abrasive suction pipe interface on the product.

2. Take out the walnut sand abrasive recovery hose elbow from the accessory storage box and attach it to the other end of the walnut sand abrasive suction pipe.

3. Take out the sandblasting nozzle tube from the accessory storage box and attach it to the sandblasting nozzle.

4. Insert the sandblasting nozzle into the round hole on the elbow of the walnut sand abrasive suction pipe.

5. Connect the quick connector of the external air source to the product’s air intake port.

6. Plug the power cable into the external power socket.

Preparatory Work

1. Open the locks on both sides of the AUTOOL HTS728 Walnut Shell Sand Blaster machine head cover, remove the cover, and take out the filter element. Then, take the walnut shell abrasive from the accessory storage box and pour it into the stainless steel tank (recommended to pour 3~5 kg of walnut shell abrasive). Reassemble the filter element and the machine head cover in sequence.

2. Take the safety goggles from the accessory storage box and wear them.

3. Remove the vehicle engine intake manifold, inspect the carbon deposits inside the cylinders and on the valves, and check whether the intake and exhaust valves are in a closed state.

4. Ensure that the sandblasting nozzle, walnut sand abrasive suction pipe elbow, and vehicle-specific adapter have been properly assembled according to their respective configurations.

Operating Procedure

1. Open the top cover of the AUTOOL HTS728 engine walnut blaster, pour in 3~5 kg of walnut shell abrasive, press the dust cover onto the walnut sand abrasive, and close the lid, ensuring a proper seal.

2. Connect the nozzle of the sandblasting nozzle to the recycling hose (there is a hole on the recycling hose).

3. Remove the engine intake manifold, ensuring that the intake pipe is in an operable state.

Insert the sandblasting nozzle into the intake pipe and rotate the crankshaft to close the intake valve.

4. Connect the air pump (not included) to the AUTOOL HTS728 carbon cleaning walnut blaster, ensuring the air source is functioning properly.

5. Turn on the power switch, and the machine will enter working mode. Select the appropriate working mode and choose the suitable speed based on the carbon deposit condition.

6. Start the cleaning process, cleaning each manifold for about 2 minutes. After finishing, stop the machine and check the cleaning effect.

7. After cleaning the carbon deposits, use the dust blow gun to expel the remaining walnut sand abrasive.

Tips

1.Air pressure up to 0.7MPa, 6bar or more air pressure.

2. The walnut shell abrasive size should be between 0.4~0.6 mm. Under normal conditions, walnut shell abrasive can be reused 5~10 times.

3. We recommend using an air compressor equipped with a dryer filter to effectively prevent moisture buildup, which can cause walnut shell media to clump and result in poor blasting performance.