AUTOOL LM120 Digital Manifold Gauges

The AUTOOL LM120 Digital Manifold Gauge uses a built-in pressure sensor to detect the vacuum pressure within the system and convert the pressure signal into an electrical signal. The microprocessor processes and calibrates the signal, then displays the vacuum level as a numerical value on the screen. It supports intelligent features such as data storage and multi-unit switching, making it convenient for quickly detecting the sealing integrity and vacuum effect of the air conditioning system.

AUTOOL LM120 refrigerant identifier Features

Wide Application Range: The intelligent electronic refrigerant gauge is an auxiliary instrument for the installation, detection, and maintenance of refrigeration equipment such as air conditioners, refrigerators, and cold storage units.

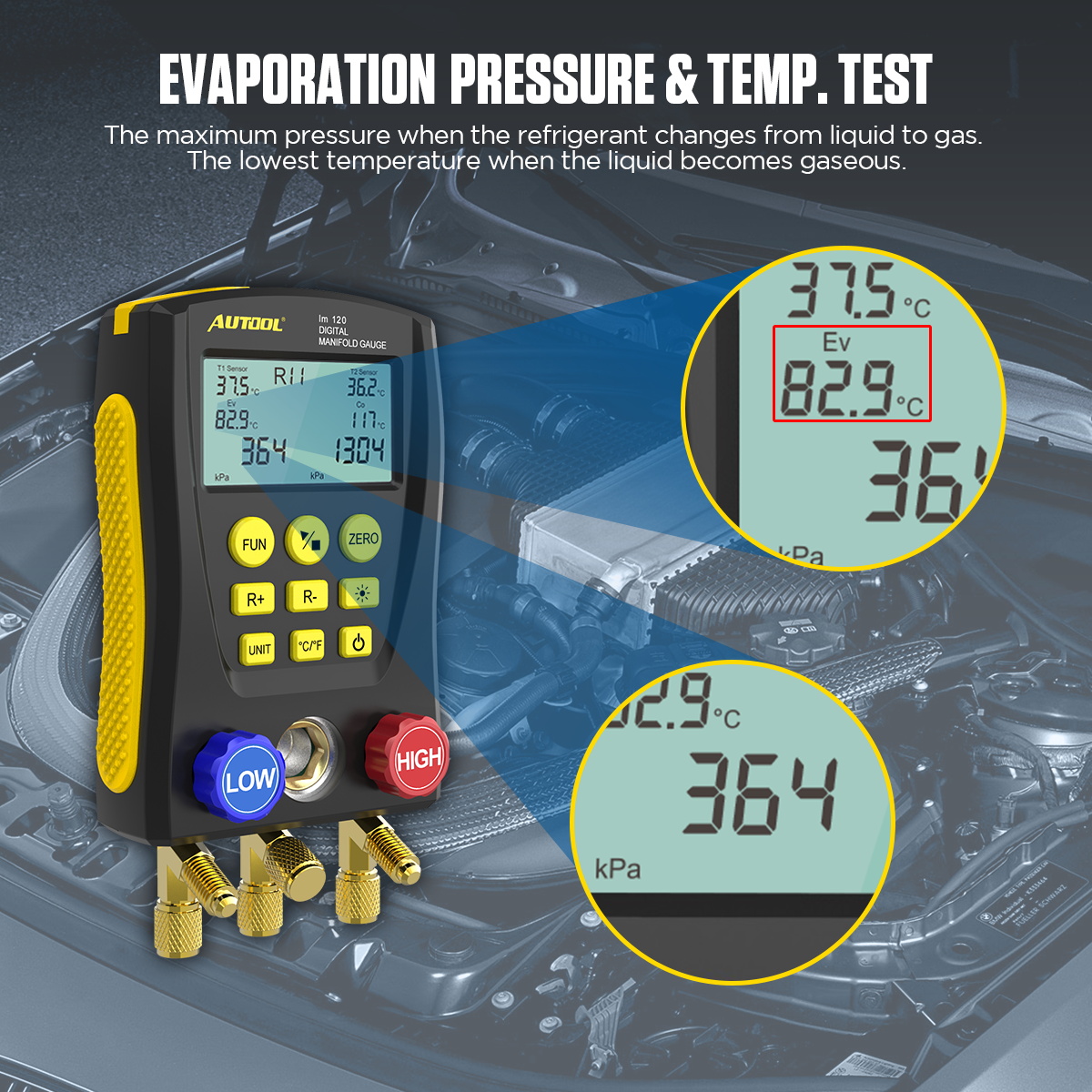

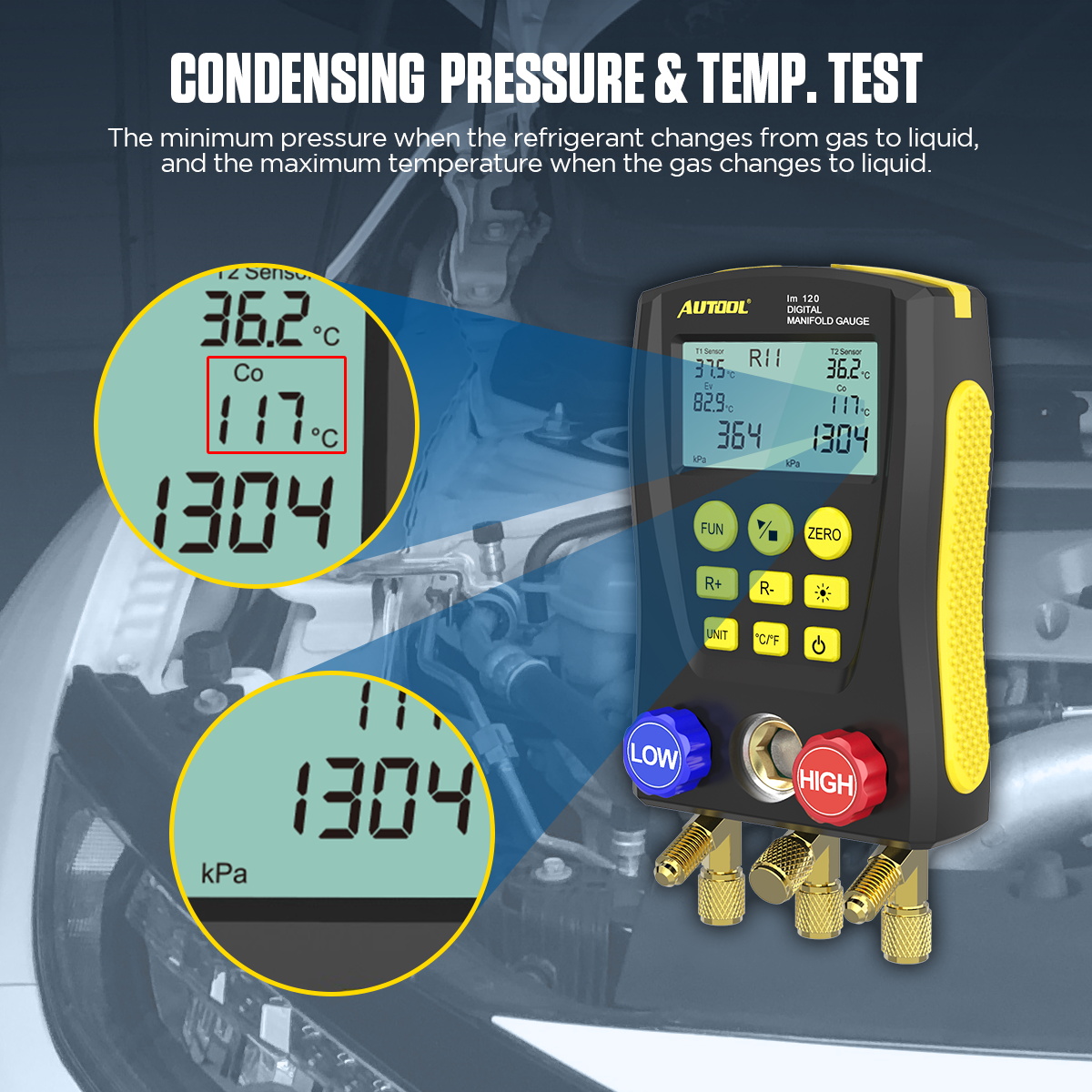

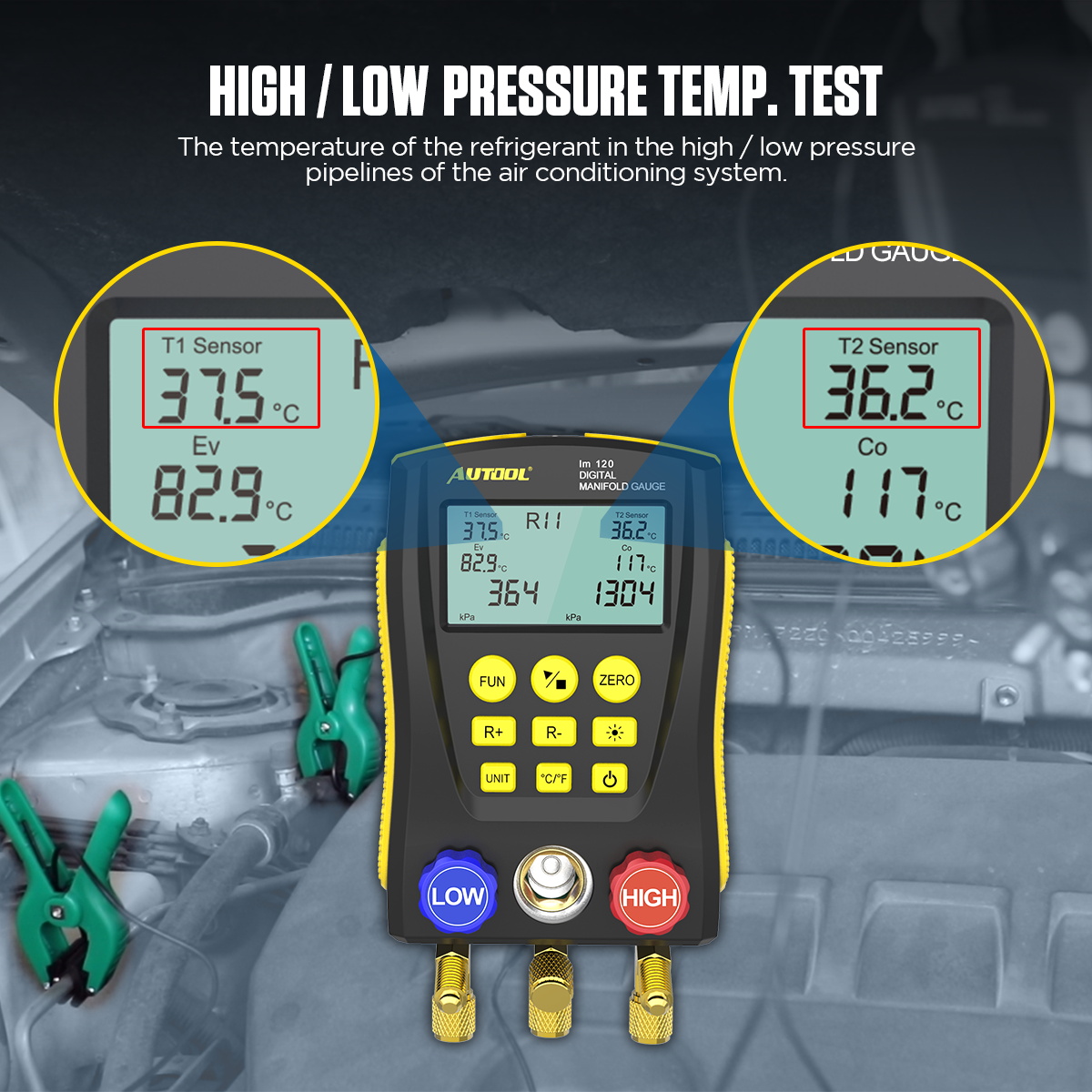

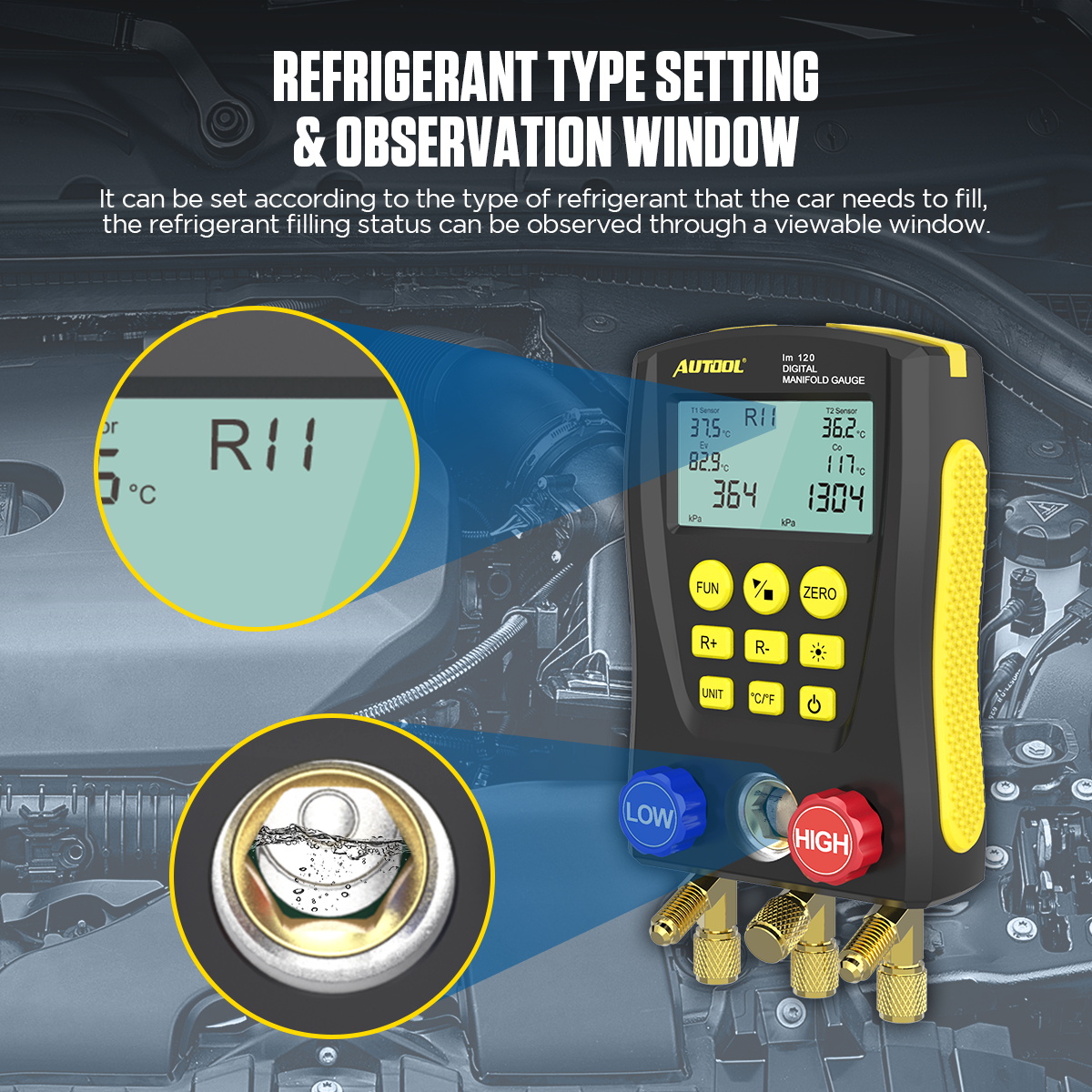

Multiple Testing Modes: It allows for dual pressure measurements (high and low pressures), dual temperature measurements (high and low pressure pipeline temperatures, requiring test clamps), and vacuum level percentage measurements. It also features pressure leak measurement, leak time and speed recording, multi-unit pressure conversion, temperature conversion between Celsius and Fahrenheit, and other functions to meet the diverse needs of users.

Intelligent Digital Display: It features a large LCD screen with backlight support, ensuring that data is clear and easy to read. Users can complete all operations using the buttons on the control panel. The display is rich in content, with the operation process and data clearly visible, significantly improving maintenance efficiency.

Built-in Database: The AUTOOL LM120 is equipped with a 32-bit digital processing unit and a high-precision data acquisition unit, ensuring high data stability. It also features a built-in database with pressure and evaporation temperature data for 89 types of refrigerants. The device can calculate subcooling and superheating temperatures, as well as analyze refrigerant pressure and evaporation temperatures.

AUTOOL LM120 refrigerant leak detector operation steps

Check the device and the air conditioning system’s condition to ensure all connections are secure and there are no leaks.

Start the vacuum gauge and select the appropriate vacuum unit.

Connect the vacuum gauge to the system interface and start the vacuum pump.

Monitor the vacuum level in real-time to ensure it reaches the standard vacuum level.

Stop the vacuum process and observe the data stability to assess the system’s sealing integrity.

Once completed, turn off the device, disconnect and store it properly.